A technoeconomic analysis of the feasibility and costs to convert Cornell district heating system to a geothermal heat source, rather than the current fossil fuel-heat water and steam was completed. A report on these analyses to the U.S. Department of Energy, “Final Report – Earth Source Heat: A Cascaded Systems Approach to DDU of Geothermal Energy on the Cornell Campus” is publicly accessible through the DOE’s Open Energy Information system.

The geothermal techno-economic simulation tool GEOPHIRES (GEOthermal energy for Production of Heat and electricity (“IR”) Economically Simulated) combined engineering models of the reservoir, wellbores, and surface plant facilities with an economic model to calculate lifetime energy production and overall levelized cost of heat. The analysis is limited to “direct use” of geothermal heat for heating buildings and for cascaded lower-temperature uses, and excludes geothermally generated electricity, which would be a low efficiency use of the moderate temperture geothermal heat we anticipate producing.

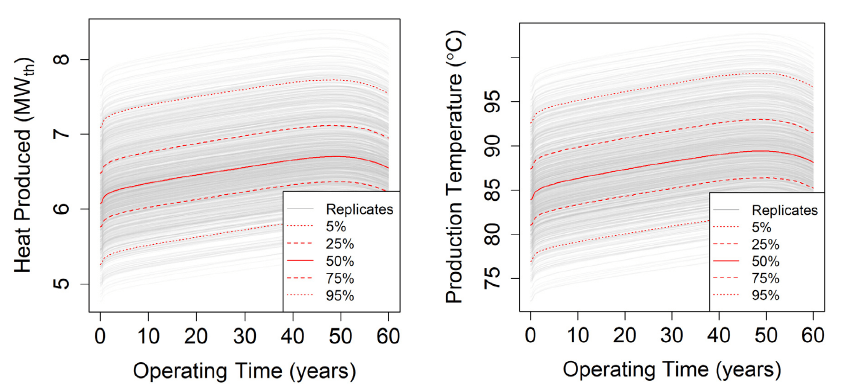

We completed preliminary model runs in GEOPHIRES to obtain initial estimates of geothermal heat production from the two target reservoirs (crystalline basement at 3.0-3.5 km depth, and a Trenton-Black River dolomite body at 2.3-2.33 km depth), for the case of serving 20% of campus annual average heat needs through provision of 5.5 MWth. Fluid and heat flow from a crystalline basement reservoir is simulated on the assumption of flow through a geometrically simple set of fractures. Monte Carlo simulations indicate heat production rates sufficient to meet this initial campus need from one set of wells are likely to be achieved. Based on a production well flow of 30 kg/s and a 30°C reinjection temperature, this system would have a longevity exceeding 50 years. To simulate the performance of a Trenton-Black River dolomite reservoir, a plug flow model is used to provide first-order estimates of the available heat. Replicates indicate heat production rates from an initial ~73°C geothermal system can exceed the needs of 20% of campus demand with an assumed production well flow of 30 kg/s and a 5°C reinjection temperature. Nevertheless, current simulations predict a reservoir lifetime of only about 20 years. Future modeling will refine the estimates, yet improved estimates also require data for more realistic reservoir parameters.